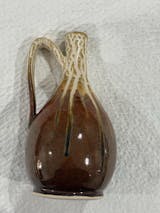

This oil dispenser is absolutely stunning and feels incredibly sturdy thanks to the large, well-crafted handle. I love the style of the glaze. It’s truly a piece of art that looks amazing on my counter.

Love these mugs. Purchased 3 to replace ones I had gotten in Maine many years ago. Design and weight is a little different. Just wish I had ordered 4!

I am very happy with quality and workmanship, as well as the color. It looks exactly as I expected. Beautiful one of a kind piece.

I bought my first piece of Blanket Creek Pottery about a year ago, and I’ve been buying one piece at a time as often as I can. I have collected many different types of pottery through the years, and this is by far my favorite.

I have been searching high and low for pottery plates with earthy colors and these plates fit the bill. I initially wanted to order the dinner plates but they were sold out. I messaged Paul and Yael questioning if they were planning to make more and I received an immediate response: YES! They made arrangements for me to make a purchase on their website for the dinner plates then proceeded to send a photo of the ones that were in the midst of creation…this made me very happy. In the meantime, I ordered the salad plates and received them within 5 days of purchase. Let me tell you, these plates are AMAZING! They match the bowls I purchased from a different artist about a year ago. Had I discovered Blanket Creek back then, I would’ve purchased every piece of pottery from them. Here is a photo of the amazing salad plate with my existing bowl…like a match made in heaven!! They were destined to be together! I’m looking forward to the dinner plates and anticipate purchasing snack plates. Thank you so much for sharing your talent and passion for quality dinnerware with the rest of the world, Paul and Yael. Every piece you make is SO worth the wait. Thank you!

Exquisite soap dispenser.

We couldn't be more pleased. It's exactly what we had hoped for. A piece of art.

Love this mug! My favorite mug broke several months ago, and I've been looking for a perfect replacement ever since. This mug is lovely, fits great in my hand (isn't too wide), and is large enough to keep up with my tea addiction.